Next generation fiber connectivity isn't just about new tools and technologies - it is about transforming old notions about field terminations while delivering compelling reasons to change, like great flexibility, cost savings and durability. As bandwidth-intensive applications continue to be the norm and the arguable perception that copper cabling is reaching its limits exapnds, a transition to fiber infrastructure is taking place. Fiber optic installations have escalated drastically and fiber-to-the-premises (FTTP) is becoming increasingly common. One thing that has been holding back widespread fiber optic adoption is the field installation of optical connectors. Thanks to 3M, not anymore.

Traditional Fiber Optic Methods

While fiber connectivity has a host of options available, each has advantages and limitations which may make them individualy good in some situations but very challenging or impossible to use in others. Heat-cured epoxy and multi-step polishing was the orginal fiber connectivity solution, used in high-volume installations. This method is still in use today, but while it is generally stable and reliable, it requires a high level of skill and a large investment in equipment. Another common method is to utilize adhesives like hot melts or anaerobic resins. Unfortunately it still requires multi-step polishing, is not suitable for higher temperatures and is also an expensive option for installers. A third common installation tact is to bypass field termination and use preterminated cable assemblies. Having absolutely precise measurements is a must for this method and errors can dramatically increase the cost - while also delaying the entire project with lead times.

From the previous iterations of fiber connection technology, we can see two common necessities:

- A fiber connector must be suitable for virtually all conditions (indoor, outdoor, excessive heat, excessive cold) and be available for UPC or APC applications.

- Equipment and tools must be affordable for reliable field installation

Enter: The 3M Crimplok+ Connector

The 3M™ Crimplok™+ Connector is the first-known, commercially available, field-mounted connector for FTTx indoor and outdoor use with no splice, gel or adhesives. Not only can FTTH drop connections be made much faster than fusion splicing, equipment savings can be 75% or more, and providers can realize considerable savings on training.

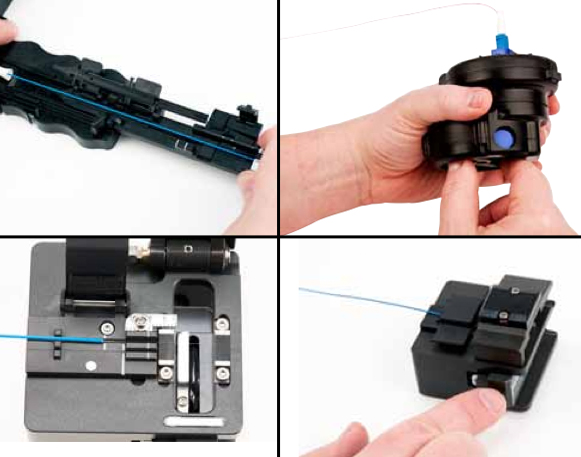

The SC/UPC and SC/APC 3M™ Crimplok™+ Connectors utilize a metallic element to mechanically lock the fiber and a simple field tool to polish it with a single turn of the handle. Since the fiber goes all the way through the connector, there is no splice or gel required. To learn more about 3M's Crimplok+ connector advantages, check out this PDF.

In addition to being ROHS compliant, the Crimplok+ connectors provide a host of features, including:

- No splice, gel or adhesive

- Fast, easy installation with no electrical power necessary

- One-piece, pre-assembled design

- A thermally balanced design

- Low insertion loss, typically about 0.2 dB

- Each connector comes with a polishing film

For more information on the 3M Crimplok+ connectors, 3M products or telecommunications solutions in general, contact your local Accu-Tech representative today, here.

.png?width=58&height=58&name=X_logo_2023_(white).png)