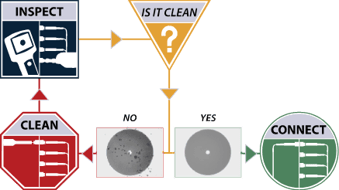

It's ironic that something as advanced as an enterprise network could be derailed by microscopic specks of debris, and yet, that's exactly what happens when you allow contaminated fiber end faces into your data center. Multiple studies point to connector contamination as the single greatest cause of fiber-related failure, so why are contaminated end faces still such a problem? In most cases, following a stringent "inspect before you connect" process every time you work with fiber can minimize contamination and prevent costly repairs.

The most critical element to safeguarding quality fiber connections is ensuring a proper end-face condition. Network uptime and signal performance completely depend on perfectly aligned and thoroughly clean end faces. When working with fibers only a few microns wide, any contaminant can be catastrophic.

The most critical element to safeguarding quality fiber connections is ensuring a proper end-face condition. Network uptime and signal performance completely depend on perfectly aligned and thoroughly clean end faces. When working with fibers only a few microns wide, any contaminant can be catastrophic.

Contaminants exist all around your network, whether it's dirt, dust or oil. These contaminants interfere with light transmission along your fiber, causing back reflection and insertion loss - all of which means your network isn't working the way it should. The allowable margin of error is tiny; by proactively inspecting and cleaning end faces, organizations will enjoy reduced downtime, optimized signal performance and minimal network equipment damage. The most common sources of fiber connector contamination include the following:

- Dust caps - these can still be contaminated from the source of production or mishandling

- Bulkheads - this is where most particles can reside due to not inspecting before connecting

- People - mishandling fiber is always a factor to keep in mind when servicing your optical network

- Environment - whether it's dust during new construction or outside in the weather, contaminants are everywhere

- Test equipment - test leads should always be inspected, and if necessary, cleaned prior to testing to prevent cross contamination

The VIAVI white paper, "Testing Parallel Optics," describes just how much damage can occur from dirt, as well as detailed instructions for inspection, cleaning and (re)inspection. Check out this white paper to learn more about how to inspect - before you connect.

.png?width=58&height=58&name=X_logo_2023_(white).png)