Contributions from Carlos Mora

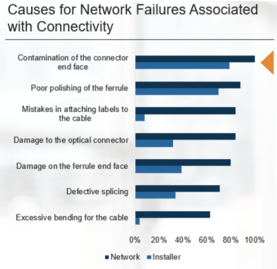

Several years ago, NTT Advanced Technology performed a  study to review the causes for network failure. The result? 98% of installers and 80% pointed to fiber connector contamination as the culprit.

study to review the causes for network failure. The result? 98% of installers and 80% pointed to fiber connector contamination as the culprit.

These findings are nothing more than a confirmation of what we already know as an industry: a clean end face is crucial to an optimally performing network. But how do you ensure your connectors are, beyond a reasonable doubt, truly clean?

After all, according to Cisco, “a 1 micrometer particle can block up to 1% of the light, generating 0.05db loss” (1). Imagine now what would happen to a single-mode fiber if a 9 micrometer particle is present-- it basically blocks the entire fiber core.

Here are some of the most common contaminants to consider:

- Dirt and dust

- Dirty tools and test equipment

- Residual contamination (i.e. oily skin)

- Ferrule cleaners

- Dust caps

This last contaminant may come as a surprise, almost counterintuitive. However, some dust caps may have a negative impact on the end face depending on the manufacturing process. Dust caps are effective in preventing scratches but not necessarily keeping particles away from the end face.

So how do we mitigate the risk of all these environmental factors degrading our end face cleanliness, and ultimately our network performance? Thanks to Corning, this utopia contractors could once only dream of doesn’t seem that out of reach.

Now, let Corning take care of the cleaning process for you.

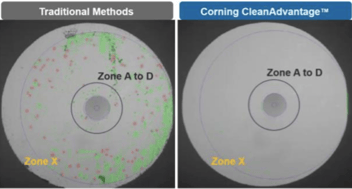

Say goodbye to the need for scoping or cleaning in the field before the first mating connection. With Corning® CleanAdvantage™ technology, the proprietary factory-cleaning process cleans the entire ferrule, making the connector not only standards compliant but also offering a peace of mind to the installer.

EDGE and EDGE8 products are now equipped with CleanAdvantage technology, denoted with white dust caps designed to fight the sources of contamination at the dust cap level. With CleanAdvantage, we ensure the following risks are mitigated during the manufacturing process.

Eliminating the need to clean these designated products in the field, we inherently speed up the install process—by up to 17 percent! CleanAdvantage technology also allows for up to 95% savings when it comes to consumables.

As a leader in optical fiber and connectivity, Corning understands the value of clean connectors to ensure optical performance. Corning also understands saving installers time and money is imperative in sustaining daily business operations. Go ahead and uncap that CleanAdvantage connector so that you can connect with confidence.

For more information, visit corning.com/cleanadvantage

.png?width=58&height=58&name=X_logo_2023_(white).png)