Many labeling jobs are subject to compliance with government- or industry-established specifications and requirements specific to that particular sector, such as ANSI/TIA-606-B for low voltage electrical environments, or OSHA/GHS standards typical for most "MRO" facilities. These standards are meant to ensure consistent appearance, accurate and reliable identification data and safety for workers and employees alike. Consequently, most "regulated" labeling must comply with the established standards, or the company can be subject to punitive action, including fines and even facility closure. That said, many companies use a "peanut butter" approach to general labeling jobs, using "industrial grade" labels for non-regulated jobs, and spending more time and money than necessary.

For example, many manufacturing plants manage sizable areas of components, parts, tools, maintenance supplies, spare inventories, etc. which require labels that are not subject to any standards. However, they use expensive "Thermal Transfer" (aka "Industrial Grade") labels when they could use "Direct Thermal" labels instead. This is especially true when labeling shelves, racks, totes, bins, boxes, moveable magnets, tool cases, etc.

A common example of "Direct Thermal" labels is the temporary "Visitor Badge" that companies print for daily use. These labels are typically inexpensive paper, not requiring any degree of durability. And the printers are fast and reliable, typically requiring NO ink, toner or maintenance, because "the ink is in the paper" (a chemical reaction creates the images by a heat-generating print head). However, because paper is easy to tear, absorbs grease, fingerprints and surface dirt, these labels were never used in a work environment - until now:

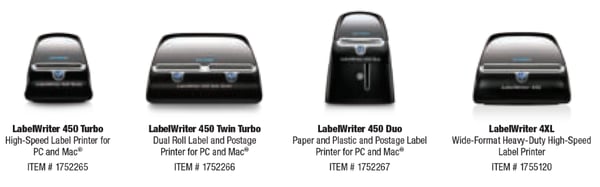

DYMO "Direct Thermal" Paper and Poly-Propylene Label Printers

DYMO Durable Labels are a water-oil-chemical resistant "Direct Thermal" material which offer a money-saving way to label many non-regulated surfaces found in plants, worksites, campuses, etc. The only requirement is that they not be used on "hard" surfaces (steel, ceramics, glass, pipes) which will be exposed to a lot of heat (in the sun, on a machine, etc.) because the "ink" will continue to "paint the label BLACK." But for totes, inside shelves, cartons, racks, supplies, parts, etc., they provide a very clean and inexpensive option instead of "Thermal Transfer" process labels. Use the free DYMO LabelWriter software to design yours now - click here!

.png?width=58&height=58&name=X_logo_2023_(white).png)