Fiber Connector Inspect/Clean/Connect Process

The requirement to inspect fiber connectors (and clean if necessary) before connection is strongly recommended in all cases; this includes the first use of new cables and transceivers or any equipment/panels with fiber interfaces.

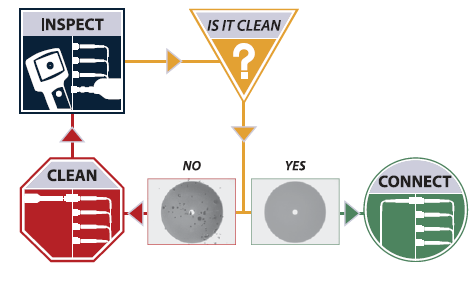

Inspect Before You ConnectTM Process Flow:

Employ the Inspect Before You Connect process as per the following diagram and steps:

Pluggable Optical Transceivers

Overview

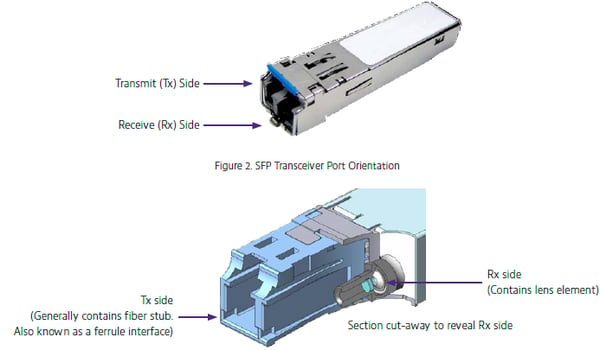

Fiber optic transceivers are highly variable in design and type: e.g. SFP, XFP, XENPAK, GBIC etc. Both the SFP and XFP have an LC connector interface; XENPAK and GBIC have an SC interface. QSFP transceivers typically have an MPO or LC interface. The key to inspecting transceivers is to understand that each port will either contain:

1. Ferrule / Fiber Stub

2. Physical Contact Lens Element

3. Non-Contact Lens Element

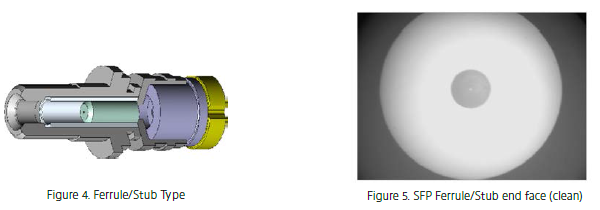

Ferrule / Fiber Stub

The Tx side of a single-mode transceiver is generally, but not exclusively, a Ferrule or Fiber Stub Interface, which is very similar to a bulkhead connector. When viewed with a video microscope, a ceramic ferrule end face will be seen. Continue reading

.png?width=58&height=58&name=X_logo_2023_(white).png)