Room level airflow management is fraught with misconceptions and half-truths, making it the least understood aspect of airflow management, although it is ironically the most important. While it’s fairly well understood that the first 3 levels, or R’s, of airflow management refer to implementing solutions such as brush grommets, blanking panels, and containment for the Raised Floor, Rack, and Row levels, respectively, the Room level isn’t quite as simple. This is largely due to the fact that the changes required are invisible, except on occasion for the displays on cooling units.

For clarity, Room level airflow management is better defined as cooling optimization, which refers to the process of making adjustments to the cooling system controls. If done well, this process will improve energy efficiency (resulting in reduced operating costs), improve cooling capacity, improve IT equipment reliability, and defer capital expenditure. It’s important to note here that without cooling optimization (i.e. Room level airflow management), every solution that has been implemented up until this point, such as the products listed above, is an expense. While they may have improved IT intake air temperatures, the financial and capacity benefits are left on the table. The only way to realize energy savings from airflow management improvements made at the Raised Floor, Rack, and Row levels, is through cooling optimization.

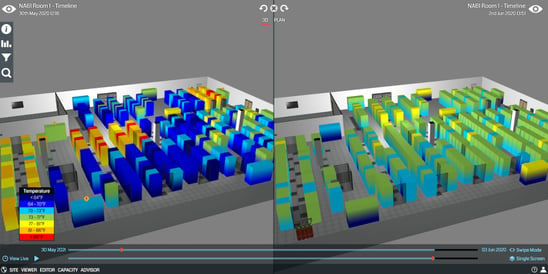

And while the process of cooling optimization is typically a manual and iterative process, it’s also important to note that utilizing solutions such as IR thermometers or environmental monitoring will ensure IT intake temperatures do not exceed their recommended or allowable thresholds. More so, some monitoring solutions can even provide advisement on specific optimization steps that can be taken, but we’ll jump into that later.

Matching Cooling Capacity with IT Load

Airflow management alone does not save you any money on cooling energy costs, instead it improves IT equipment intake air temperatures and creates the conditions where changes to the cooling infrastructure are possible. Reason being, if you have implemented airflow management solutions at the Raised Floor, Rack, and Row levels correctly, you should now have an excess of conditioned supply air in your cold aisles and all IT equipment intake air temperatures will be excessively low. This is because there is no longer any mixing of exhaust air with conditioned air, and vice versa. The next step is to match the flow rate of conditioned air as closely as possible with the demand flow rate required by the IT equipment. This is done by lowering fan speeds, raising cooling unit temperature set points, or turning cooling units off altogether. This is often an iterative process of making adjustments to controls, allowing the system to equalize, and then making additional adjustments if needed. In addition, as data centers are dynamic environments, this will also be an ongoing process – not just a one-time event. Each time additional airflow management improvements are implemented, or significant IT equipment changes occur, there are opportunities for optimizing the cooling infrastructure. Continue reading

.png?width=58&height=58&name=X_logo_2023_(white).png)